Retrofit

By critically evaluating your air technology installations, adjusting them better and replacing or cleaning parts, you can quickly save a lot of energy!

- Expansion with or renewal of heat recovery, cooling or humidification

- Use of energy efficient motors and/or fans with a better energy efficiency

- Renewal of cooling, measurement and control technology

Retrofit of air technical installations

Possibility of replacing/or expanding with the following components

○ Plate heat exchanger

○ Rotary heat exchanger

○ Heat pump

○ Hybrid heat pump

○ KV system - Twin coil (water/glycol)

○ Accu block

○ Adiabatic systems

○ Humidification systems

○ Valve register

○ Flexible connections

○ Control equipment

○ Coatings

○ Air filters

Retrofit

Outdated ventilation systems cost a lot of money year after year, are maintenance intensive and have high emissions.

The solution: modernization.

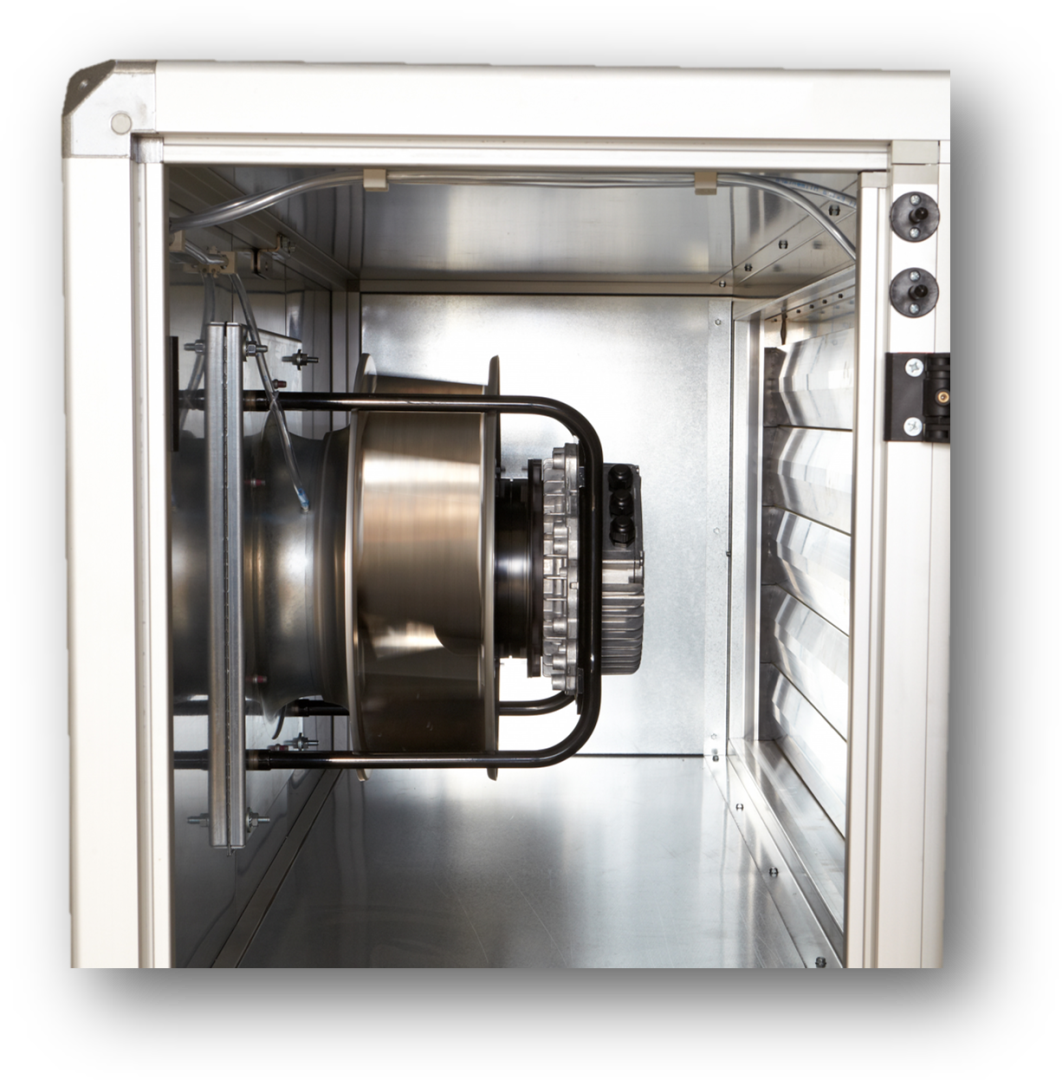

By modernizing your old systems with our energy-efficient fan systems, you can make huge savings on operating costs.

Replacing the fan reduces power consumption and maintenance costs and minimises emissions.

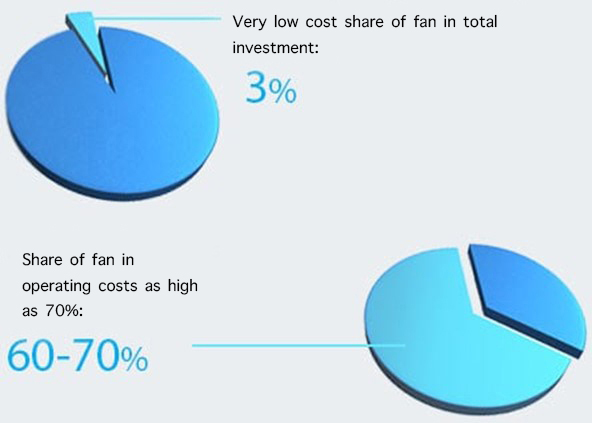

A fan represents up to 3% of the investment cost for an HVAC system.

However, the fan's share of operating costs is as high as 70%. This results in a huge savings potential that you should take advantage of.

Our comprehensive service package allows us to put together exactly what meets your requirements. Make use of our free analysis and we will offer you the best solution.

For example:

A plug fan is not always the most suitable solution for your HVAC system. We analyze your project, compare different options and always find the ideal solution. Our fans ensure an optimal cost-benefit ratio.

The energetically best fan always pays off.

Pollution in air technical installations

An air conditioning system should be seen as the lungs of a room or building and can only produce clean air if it is clean itself.

In order to comply with the IDA standard, your units must be cleaned and maintained regularly

- Contaminated filters cause premature corrosion

- Recent research has shown that COVID-19 viruses have no chance when using H14 filters.

- Regular cleaning of heat exchangers saves energy costs through reduced pressure loss and optimal heat exchange.

Antimicrobial film coating

The requirements for indoor air (IDA) are particularly high, especially in medical and pharmaceutical areas, but also in production processes a permanent antimicrobial coating offers additional protection.

The effectiveness of this coating against multi-resistant germs is also a particular advantage in laboratories, hospitals and nursing homes.

The substances in the surface coating reduce and even inhibit the growth of multi-resistant microbes and bacteria and activate their protective properties when conditions are favorable for bacteria, fungi and algae.

Moreover, this has a dual effect : on the one hand, the growth of germs is inhibited, on the other hand, existing germs are eliminated!